Rogers EHF-100 MK2

P.O.A.

The Rogers EHF-100 is more than just good sound and good value: It’s good news. Very highly recommended. –Art Dudley, Stereophile Magazine

Never before has music sounded so good coming out of your speakers. Clarity rules with the EHF-100 MK2. Trust us. Turn it on and youʼll be blown away by the concert hall quality. There may be other tube amps on the market, but nothing compares to the power and precision of this amp. The sound is stunning and so is the look. All you have to do is close your eyes and immerse yourself in the music.

FEATURES:

- Made In The USA– Hand built to the most exacting specifications in our New York Facility. All amplifiers are fully evaluated and acceptance tested using the the best audio test equipment made by Audio Precision. We perform all of the tests in a typical Stereophile test evaluation and many more to characterize each amplifier. Each amplifier is shipped with a fully evaluated test data package so that the customer can see how his particular unit performed after acceptance.

- Transferable Lifetime Limited Warranty- Our Products are guaranteed FOR LIFE.

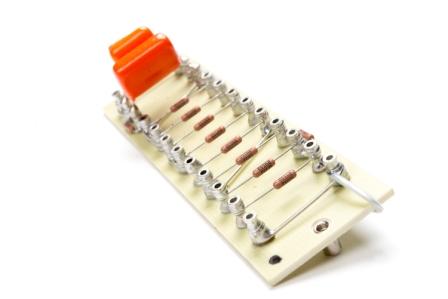

Completely Hand Wired– The entire amplifier is wired by hand using all American labor in NY. The wiring is all discrete components and all point to point. This provides a lifetime of serviceability and reliability. All of the wiring and soldering meets the Military Standard 2000 requirements. All operators are trained to this standard.

Completely Hand Wired– The entire amplifier is wired by hand using all American labor in NY. The wiring is all discrete components and all point to point. This provides a lifetime of serviceability and reliability. All of the wiring and soldering meets the Military Standard 2000 requirements. All operators are trained to this standard.

- Aerospace Specifications- All of our resistors, capacitors, transformers and inductive components meet or exceed the applicable military quality standards for parts selection. We use the same parts used by NASA in the Shuttle and Space Station equipment.

LEARN MORE ABOUT OUR COMPONENT SELECTION HERE

- Aviation Grade Chassis- All amplifier chassis are aviation grade aluminum with a mutiphase powdercoat and clear coat finish. The amplifier finish is absolutely beautiful and bulletproof! The front panels are machined from solid blocks of aviation grade aluminum. The entire amplifier is assembled using Military Standard stainless steel hardware for ultimate reliability and a lifetime of trouble free service. All hardware is meticulously staked using an aerospace coating to eliminate any hardware failures over time through vibration, shipping or movement. This is an assembly process honed over many years of satellite manufacturing and assembly where re-tightening hardware can’t happen.

- Internal Wiring– The entire amplifier is wired using 18 gauge Military Standard 16878 teflon coated, silverplated copper wire. This is the same wire used for the Navy’s Aegis Cruisers! Heat is the enemy of amplifier reliability. Because this is a Class A design, there is some heating of the unit which causes the wiring to age and degrade over time. Our wire never ages. The teflon coating will last a lifetime. The interior of your amplifier will look the same in 10 years as it looks coming off of the production line. The amplifier is designed using all 18 gauge wire to provide many times more the current density than can be achieved using printed wire boards or lower quality wiring.

WATCH HOW HEAT AFFECTS LOWER QUALITY WIRING

- Auto Bias– Self Bias circuit for adjustment free operation and longest tube life. Customer does not need to adjust tube bias. As the tubes age, they adjust for bias changes automatically. The customer can change tubes at any time or replace a single tube rather than the full set of 4 and the amp will automatically re-bias for the change.

- Class A Design– All amplifiers are a full Class A design yielding the ultimate accuracy in music reproduction.

- Pentode Input Stage Utilizing An EF86– This is an ultra low noise, high gain tube designed for high fidelity applications and has an internal shielding network. All of the overall gain is in this single stage. This significantly reduces phase distortion and yields a dynamic, stable soundstage with terrific dimensionality.

- Burn-In Process– Each amplifier undergoes a rigorous 100 hour burn-in prior to acceptance testing. This drives out any component infant mortality problems and ages each amplifier into it’s perfect listening range.

- Manufacturing Process– All amplifiers are built using our own Statistical Process Control manufacturing processes that yield better than a 99.8% first pass yield.This is better than the airline industry’s or hospitals’ safety record. The finished amplifier is 100% reliable, tested and guaranteed for a lifetime.

Binding Posts– We use Furutech binding posts for all amplifier designs. These are solid copper posts milled from OFC copper billets and then Rhodium plated with carbon fiber insulators. They are simply the best the industry has to offer. All inputs are gold plated RCA connectors.

Binding Posts– We use Furutech binding posts for all amplifier designs. These are solid copper posts milled from OFC copper billets and then Rhodium plated with carbon fiber insulators. They are simply the best the industry has to offer. All inputs are gold plated RCA connectors.

- Power Measurement System– Each amplifier has a tuned, power measurement system that allows for flawless system integration and adjustment.

- Remote Control– The remote control provides 100% analog remote volume control. This feature eliminates any solid state components in the signal path which can compromise the analog, tube sound.

- Shipping– Each amplifier is shipped using a 2 box, double wall container system that has diecut, high density and low density foam vibration absorption material. This shipping system is designed to withstand a drop on all 6 box sides from 3 feet and produce no amplifier damage. We have NEVER had an amplifier returned for shipping damage.

SPECIFICATIONS

EHF-100 MK2

- Tube Complement: 2-EF86, 2-12AX7, 4-KT88

- Frequency Response: 65 Watts RMS Per Channel/0.1dB from 20Hz to 20kHz with Less Than 0.1% Total Harmonic Distortion

- Gain: 40dB

- Input: 4 Unbalanced, 100k Ohm

- Output: 4 Ohm

- Weight: 50 Lbs.

- Dimensions: 17″ width, 14″ depth, 10″ height

- Power Cable: Standard Cable Included, Rogers High Fidelity Quiet Cable Optional

- Fully Analog Remote Volume Control Function